culture center 企业文化

01mission

企业使命提供超出客户预期的散料输送方案和服务,为客户创造最大价值

02vision

企业愿景成为散料输送行业领跑者

03values

企业价值观团结、高效、求精、创新

解决方案致力于把公司打造成国内乃至国际化的散料输送引领者

更多探索>

产品中心

散料输送产品研发高新企业

散料输送产品研发高新企业

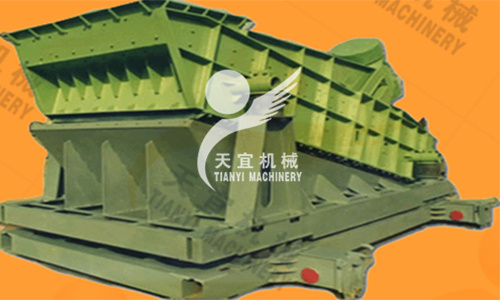

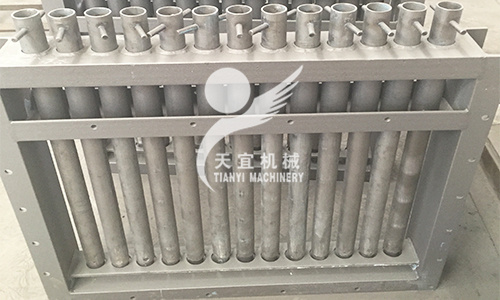

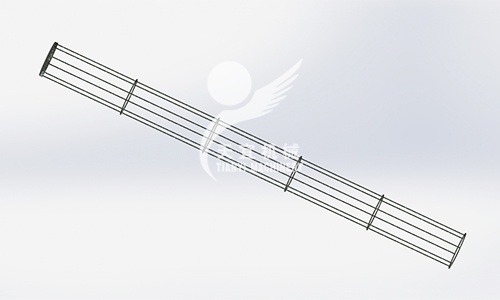

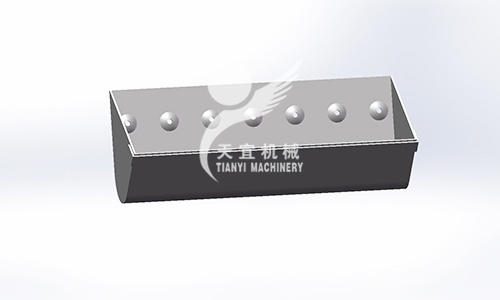

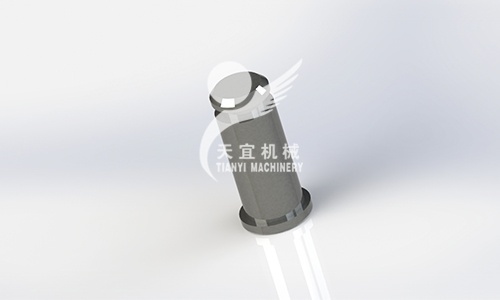

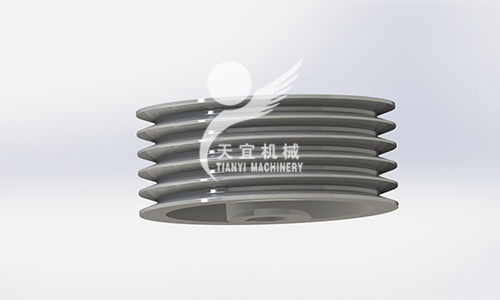

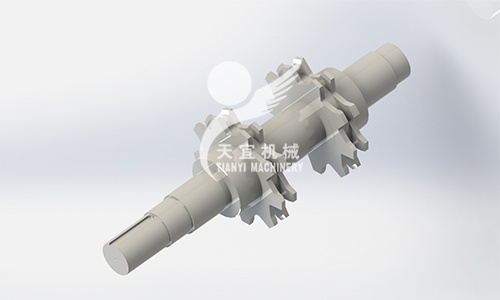

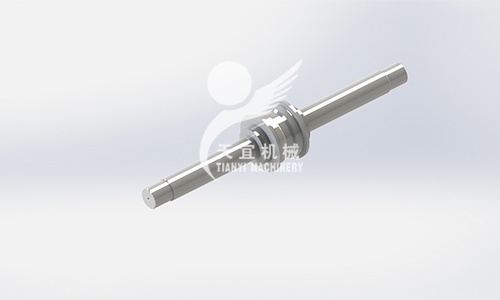

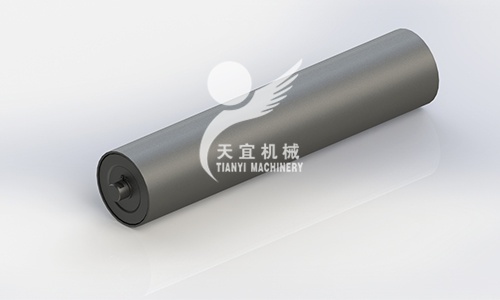

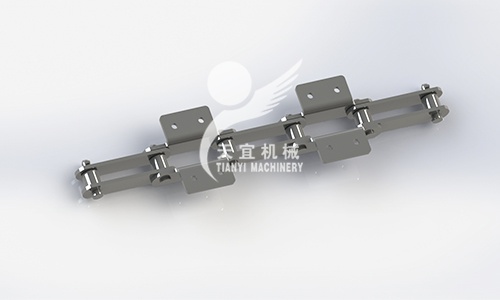

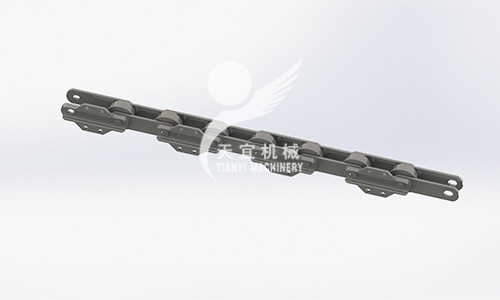

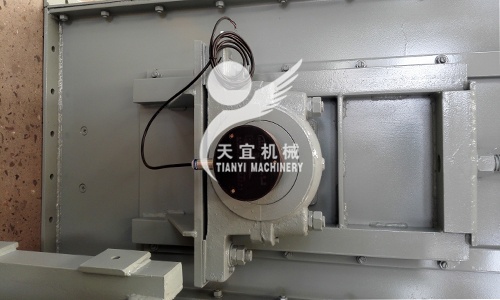

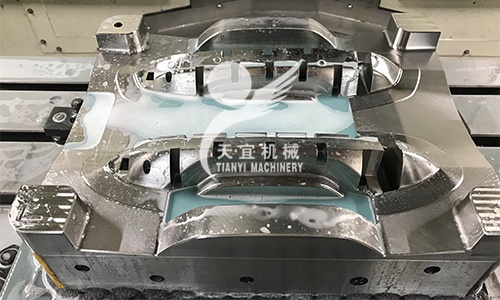

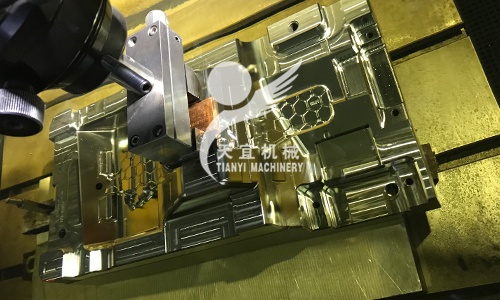

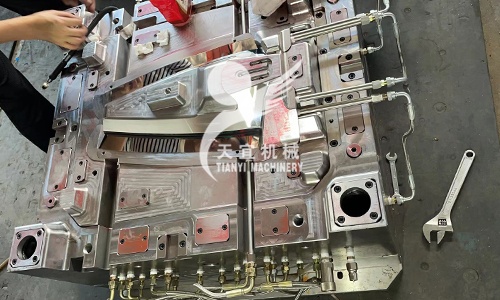

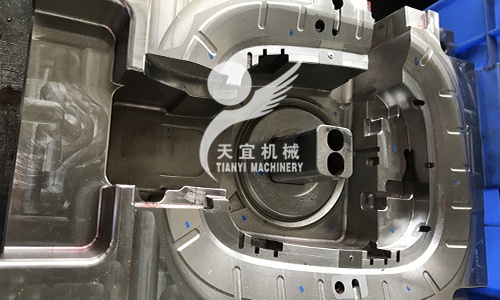

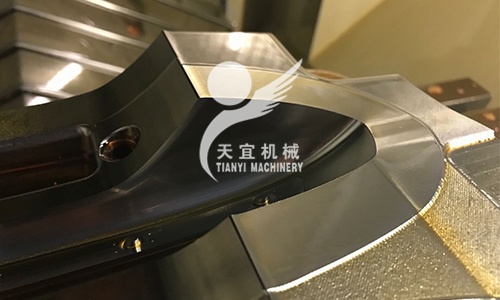

公司主导产品有埋刮板输送机、斗式提升机、螺旋输送机、除尘器等散料输送设备,广泛运用在冶炼、煤化工、火电、环保等领域,产品畅销全国,部分产品远销东南亚、非洲等国家和地区。

→

“精益求精,开拓创新”湖北天宜机械股份有限公司

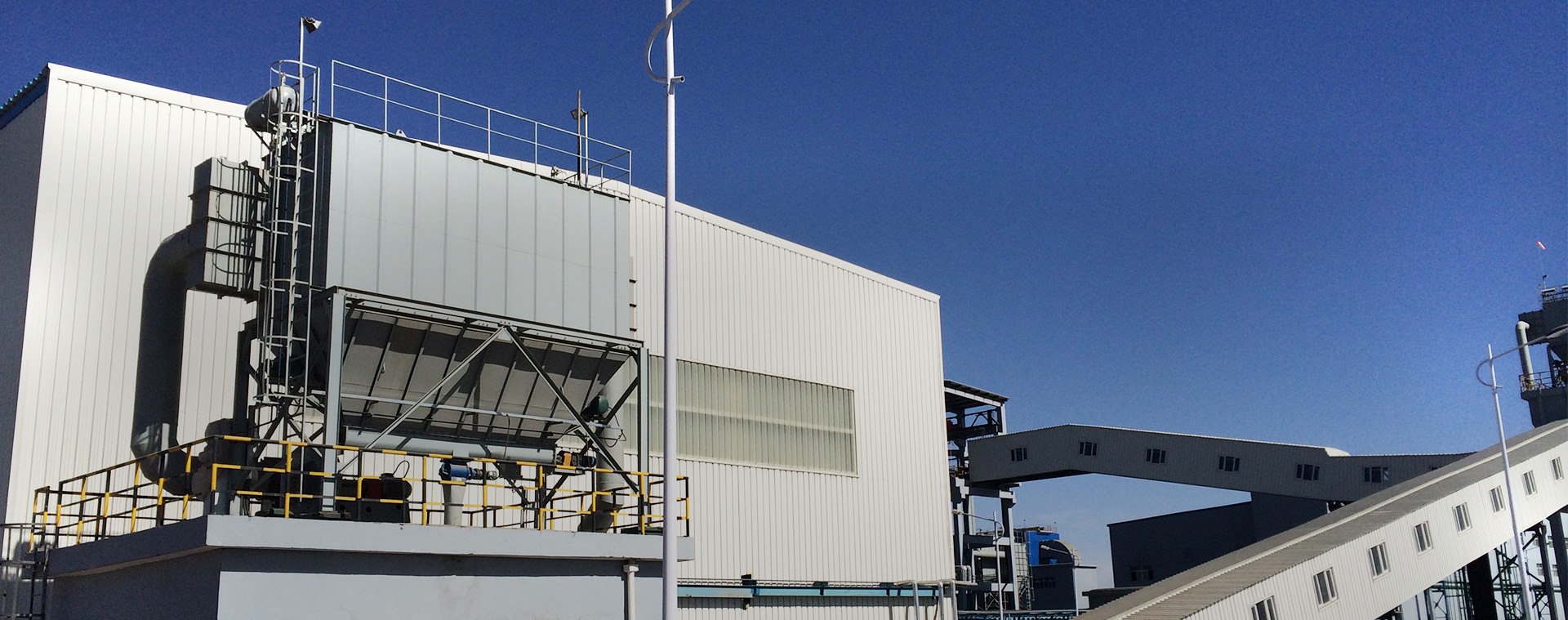

湖北天宜机械股份有限公司是一家集设计、 制造、 安装、 调试输送设备、 破碎设备、 筛分设备的高新技术企业. 公司位于湖北省宜都市,隶属于三峡宜昌“半小时经济圈” ,鄂、 渝、 湘三省市交界处,距离举世瞩目的三峡大坝50余公里,距离三峡国际机场20余公里,焦柳铁路及长江、 清江贯穿南北,形成了空中、 陆地、 水上立体运输网络,为人文交流、 物流运输提供了方便快捷的服务.

公司始创立于

2007年

公司总占地面积

70000平方米

“新三板”成功挂牌

2015年

了解更多 >>